Product

Junction Box Power Distribution Board Local Control Station

Efficiency and productivity became more and more important for manufacturing Industries. Automation and Control System became the backbone that can help you to achieve success to became more productive and efficient. We are expert in providing Automation and control system solution in all levels of factory and process automation system from management and operation level, control level, and field level. We have extensive experience with numerous applications in various industries.

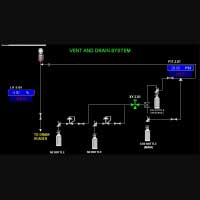

Factory Automation and Process Automation System

Operation Level:- • Distributed Control System (DCS)

- • SCADA System

- • Energy Management

Control Level :- • Programmable Logic Controller (PLC)

- • Human Machine Interface (HMI)

- • Industrial PC (IPC)

-

Field Level :- • Distributed I/O

- • Remote I/O

- • Power Supply and Distribution

- • Drive system

- • Process Instrumentation

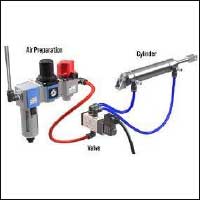

- • Pneumatic Cylinder

- • Solenoid Valve

- • Process valve

Application

- • Remote Terminal Unit (RTU)

- • Fire & Gas Systems

- • Engine Genset Control System

- • Emergency Shutdown System (ESD)

- • Heating, Ventilation, and Air Conditioning (HVAC) Control System

- • Water and Wastewater Control System

- • Power and Control Redundant System

Industry

- • Oil & Gas

- • Water & Wastewater Treatment Plant

- • Pharmaceuticals

- • Chemical & Petrochemical

- • Tunnel

- • Construction

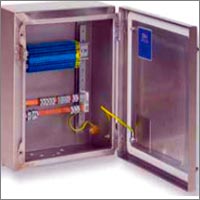

Junction Box Power Distribution Board Local Control Station

Technical specification

Weather proof enclosure or cabinets IP65/IP66 can be applied for Power Distribution Board, Local Control Station, Junction boxes and other application suitable for outdoor environment. Variety materials and sizes of enclosure depend on specific requirement.

TSheet steel

Sheet steel enclosures and cabinets are manufactured from steel material with powder coating RAL7032. The degree of protection is IP 65/66. Sizes of enclosures can be tailor-made to customer specific dimensions.

Thermoplastic

Thermoplastic enclosures are light, corrosion free with high impact resistance. Wide range of sizes as per manufacture standard The degree protection of enclosures other than modular types is IP 66/67

Stainless Steel 304/316

Stainless steel enclosure and cabinet are manufactured from 304/316L material, natural or hairline finish with hinged door or screw cover type. Gasket is continuous polyurethane with gland plate as an option on each side The degree of protection is IP 65/66. Sizes of enclosures can be tailor-made to customer specific dimensions.

Junction Boxes/Cabinet Local Control Station

Technical specification

Enclosures are suitable for installations in areas where explosive atmosphere of gases, steam and dust can appear (i.e. in Zones 1 and 2 in gas areas and 21 and 22 in dust areas). Various sizes of hinged door & screw cover type are certified by ATEX and IECEx. ENSTO is experts in providing customer- specific Ex enclosing solutions for hazardous areas. Standard enclosures can be delivered with a multitude of optional solutions and features such as any dimension, material, surface treatment, RAL color, flanges and windows. In addition, we provide special design enclosures developed together with customers according to their needs. Maximum size up to 1000(W) x 2000(H) x 800(D) mm

Material : SS304/316

Surface treatment : Hairline/Brushed

Gasket : Special closed-cell gasket

Degree of Protection : IP66

Impact resistance : 7Nm

Operating Temperature : -55…85 oC

Ex empty Certificates: Presafe 14 ATEX 5378U, IECEx PRE 14.0042U.

Standard Marking Junction Boxes: II 2G Ex e IIC Gb

Standard Marking Control Station: II 2G Ex de IIC T6 Gb

UPS/Battery Charger Power Distribution Board

Technical specification

Custom designed for use in Zone-1 and Zone-2, type of protection is II 2 G Ex d IIB+H2 T6/T5 and degree of protection IP66/IEC 60529. Certification according to ATEX directive. Providing a complete system solution for motor control centre, UPS or Battery charger in one integrated package including free standing rack.

Enclosures specification:

II 2GD Ex d Cast aluminum boxes , epoxy painted RAL color, Stainless Steel screw bolt, hinged door type. Enclosures are available in wide range of sizes to house breakers, staters, control units, and electronic cards, relays meters, etc.

Frame/Rack

Structural steel channel welded and bolted. Standard finishes is Hot dipped galvanized steel or painted.

Features

Complete factory assembles, panels are interconnected through bushing and wired . Reducing maintenance time and cost by having control grouped. Custom build racks designed to meet the requirements

Battery Bank

Technical specification

Battery enclosures are suitable for installations in areas where explosive atmosphere of gases, steam and dust can appear

(i.e. in Zones 1 and 2 in gas areas and 21 and 22 in dust areas) in AISI 316L stainless steel. Certification includes

a wide range of cells up to 120V, 2000Ah including Ex d battery isolation switch as an option.

Suitable for:

1. Engine operating pumps

2. Solar panel application

3. UPS system

4. Telecommunication system

5. Emergency light.

6. Others application need Ex e batteries.

Material : SS316L

Surface treatment : Hairline/Brushed

Degree of Protection : IP43

Impact resistance : 7Nm

Operating Temperature : -55…85 oC

Certificates: INERIS 12 ATEX 0061 X.

Standard Marking Control Station: II 2G Ex e IIC T6 Gb

EHT Total Solution

Technical specification

Heat trace provides a way to cover heat losses on a pipe, vessel, tank, or equipment using a line of electrically heated cable to maintain specified temperature. We provide detail engineering from initial stages through final installation and commissioning.

Heating cable

Heating cable selection is depend on the heat losses and product temperature to be maintained during the proses. There are 2 types of common heat trace cable which is self regulating and mineral insulated heating cable

Control Units

To control specified temperature range are not exceed it. Type of control unit:

1. Capillary tube model build with PT-100

2. Digital Controller can be connected to PLC

Insullation

Reducing heat losses along the object to maintain the product running well to avoid proses failure. Insullation material are mineral wool, glass wool, calcium silicate and etc to be covered with aluminum cladding.

Power Panel and Control Panel

Power distribution board is depend on the line of heat tracing with individual earth leakage protection. Monitoring of individual line heat tracing by controller can be provided. Panel is available for weather proof and explosion proof application.

Technical specification

Armor-X is new improved continuously-welded armored with strength, endurance flexibility live up demands of most difficult job without cracking armor. Plus, cable offers a smaller diameter lighter weight than the competition, making it easier to install even in tight corners and areas requiring multiple bends. For use in Classes I, II, and III, Division 1 and 2 hazardous locations covered under NEC Articles 501, 502, and 503. Cable applicable for MV and LV continuous, corrugated aluminum armor provides a sheath impervious to moisture, liquids, and gases. Cable is flame retardant UL- listed for cable tray use, direct burial, sunlight resistant and minus 40°C installation temperature. Continuous aluminum sheath meets the grounding requirements of NEC 250-122 in non-HL locations. Cproven, flexible EPR insulation. SOLONON low smoke, non halogen polyolefin jackets

Benefits of ARMOR-X

- Twice the flexibility endurance of other

- armored products

- Low bending force to withstand greater pressure

- Similar flexibility resistance to other products

- Smaller diameter

- Lighter weight

- Works with all standard hardware.

Cable is manufactured and tested in accordance with the latest revisions of the following standards and specification:

•UL 1072, UL 2225 and UL 1309

•ABS Listed as CWCMC.

•ICEA S-93-639 (NEMA WC 74) - 5-46 kV Shielded Power Cable for Use in the Transmission & Distribution of Energy.

•ICEA T-29-520 - Vertical Tray Flame Test (210,000 BTU/hr.).

•IEEE 1202/FT4 - Flame Testing of Cable for Use in Cable Tray in Industrial and Commercial Occupancies with CPE and Solonon jacket.

•AEIC CS-8